Green agenda, net zero emissions and the environment: The future of automated logistics

Kearney, the well-known US research and consulting firm, estimates that 80% of consumers assess the environmental impact of their purchases. A sustainable approach is a complex but necessary path to take. In addition, this is true not only for individuals, but also for companies and corporations, which are paying increasing attention to sustainability.

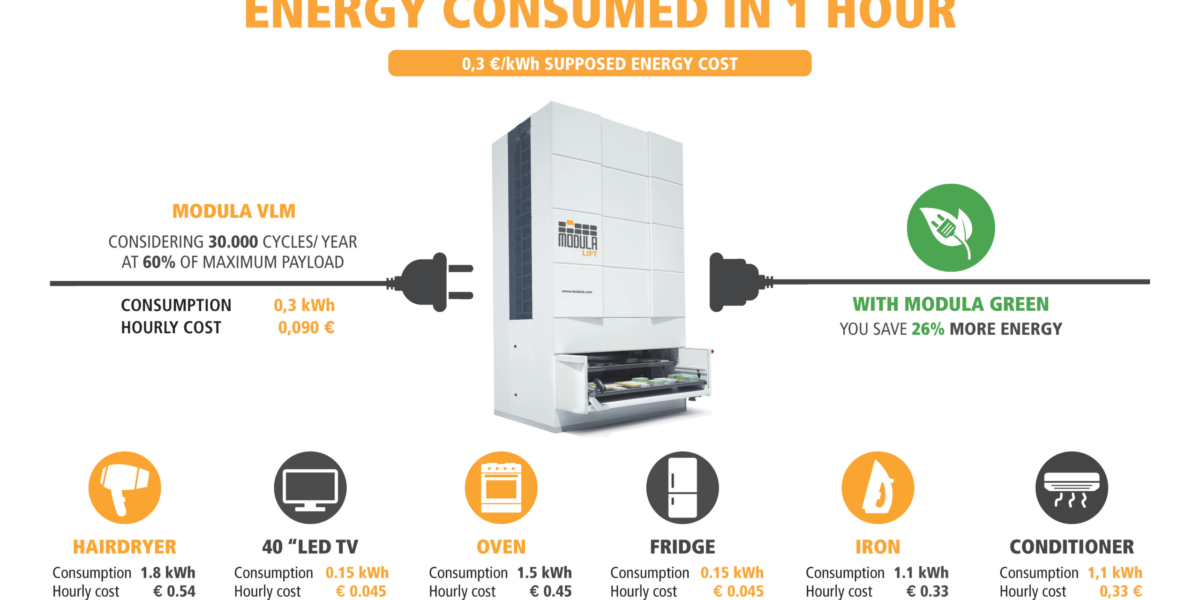

We cannot ignore this trend and, while for some time now there has been talk of separate waste collection, energy reduction (a vertical storage system consumes only 1.2 kWh) and the reduction of the so-called carbon footprint, today we must broaden our view. Switching to LED lamps or streamlining production as well as upgrading HVAC systems is not enough. For business leaders, making decisions regarding corporate sustainability has become a more complex process nowadays, one that must take into consideration many new factors.

All companies, especially those operating in manufacturing and distribution, are developing strategies to align with the 2030 Agenda for Sustainable Development. Therefore, sustainability becomes an integral part of strategic planning, which involves all of the main business activities, from operations within the plant to process functions.

That’s why this is the right time to rethink the environmental impact of your warehousing operations.

Choosing to automate storage systems is not only the most appropriate solution to improve your company’s logistics processes, but it can also be an environmentally friendly decision for a more sustainable future.

Distribution and the 3 essential elements in warehouse sustainability

This issue is especially relevant for supply chain companies. In its recent State of Logistics Report 2022, the Council of Supply Chain Management Professionals (CSCMP), the leading professional association for the promotion and dissemination of research and knowledge on supply chain management, indicated that: “industrial, manufacturing and logistics companies, as major consumers of energy and historical sources of carbon emissions in the global economy, must play a leading role with regard to sustainability. Better synchronized supply chains, aligned with shared sustainability goals, are essential to achieve greenhouse gas reduction goals.”

Did you know that freight transport is a major contributor to global carbon dioxide emissions? And that warehouses, especially those with refrigeration, are among the most energy-intensive industrial structures on the planet?

According to Cascade Energy, an industrial energy management company, energy consumption is the second highest operating expenditure in refrigerated facilities, preceded only by labour costs. Imagine the impact this can have on food and food distribution warehouses, where refrigeration consumes about 50% of total energy, a value that reaches 65-75% in fully refrigerated facilities.

We are therefore faced with a great challenge: on the one hand, warehouses must become larger to meet the ever-increasing growth objective and the ever-increasing demand; on the other hand, it is necessary to reduce costs, especially in the current economic situation, as well as the environmental impact of distribution operations.

What does it mean to make a warehouse sustainable? What are the steps to take?

Let’s start from the 3 cornerstones of sustainability, those that should guarantee the new generations a future with the same or a greater level of well-being while protecting the planet and the environment.

Environmental pillar, social pillar and economic pillar:

- a) Environmental pillar: initiatives aimed at reducing the company’s carbon footprint.

- b) Social pillar: initiatives aimed at promoting the well-being, health, and safety of employees and customers.

- c) Economic pillar: initiatives aimed at ensuring the prosperity of the company while achieving positive results on both the environmental and the social front.

What steps can be taken to improve the environmental impact of logistics?

Order fulfillment activities can be made more sustainable through a series of transformations. In this case, we are talking about a real change towards sustainability that introduces automated picking solutions into company logistics.

For the fulfillment of orders of small quantities, the “goods to person” principle becomes a necessary approach, in fact it is widely used in the context of automated warehousing. It is the goods which move towards the operator, in an automated, innovative and high-performance flow that greatly improves the order preparation process.

The real advantage of automated order fulfillment lies in that goods can be stored in a reduced space while picking and order preparation are much easier for the operator, who remains in an almost stationary position.

This is optimal for picking activities, in fact in this phase operators are more efficient compared to when they have to move around the warehouse to look for the ordered products.

Let’s analyze two automated storage systems based on the “goods to person” concept and take a look at how they comply with the requirements of the “Three Pillars of Sustainability.”

Being able to handle thousands of different items, Modula’s automatic vertical and horizontal storage solutions allow goods to be stored, picked, and packed with a very high level of efficiency, while simultaneously supporting sustainability.

Pillar 1: Vertical storage systems and environmental sustainability

Let’s see how Modula automatic vertical and horizontal storage systems are designed to support environmental sustainability.

1) Space and storage optimization

Modula automatic vertical and horizontal storage systems are the sustainable solution par excellence, thanks to their ability to optimize space. With Modula automatic storage systems, storage in tight and compact spaces becomes possible. The footprint of goods in a Modula storage system is significantly reduced, up to 90%. As a result, it is possible to concentrate logistics operations in a small area, improving the flow of activities and speeding up all related operations. In addition, the need to store goods in locations away from the company’s premises is reduced.

If we pay attention to the structure of automatic vertical storage systems, we can see that one of its most relevant features is the possibility of storing goods up to 16 meters from ground level, taking advantage of the space available between the floor and the ceiling. The space inside an automatic vertical storage system is also designed to ensure maximum capacity. In fact, the trays inside the machine can be used up to 90% of their capacity, roughly twice the 40% capacity usually taken up in traditional racking systems.

Modula automatic vertical and horizontal storage systems are designed to be scalable and modular. Thanks to these characteristics, their configuration can be easily changed, and the storage structure can be larger or smaller according to the specific needs of the company.

These storage solutions can thus adapt, for example, to production needs or vary according to the number of SKUs to be handled, both in the case of storage at room temperature and in the case of storage at a controlled temperature to 0°C, which is one of the most energy-consuming processes.

In general, therefore, storing goods while making better use of space means building less, having a smaller impact on the environment and certainly polluting less.

2) Energy savings and recovery

In the context of the growing interest in energy management and the continuous search for energy saving solutions, Modula automatic vertical and horizontal storage systems can be the right answer.

The overall energy consumption is very low (about 1 kWh for the Modula Slim) and consumption only starts when the operator calls a tray to the bay. In fact, the automatic storage systems are electrically inactive the rest of the time, with stand-by consumption close to zero. Modula storage systems are also designed for energy recovery, in fact, if equipped with Modula Green – an energy recovery device consisting of an inverter that generates energy from the downward movement of the lift – they recover the energy to power the machine. Indeed, the kinetic energy produced by the descending lift is transformed into electricity, which is then used for the ascending movement. With Modula Green, energy savings reach 40%

3) Elimination of CO2 emissions from forklifts

With automatic vertical and horizontal storage systems, forklifts are no longer necessary, and their emissions are also eliminated. Thanks to the goods to person paradigm, movements around the warehouse are significantly reduced, as is the need for tools like forklifts and AGVs, which can largely be eliminated along with their recharging or refueling stations.

Pillar 2: Vertical storage systems and social sustainability

What benefits can people obtain from automatic vertical and horizontal storage systems?

1) Better working conditions

Automatic storage system operators can benefit from a substantial improvement in their working conditions, in particular with regard to health, well-being and safety. We can classify these 3 benefits as social sustainability factors, not always recognized as such, but noteworthy nonetheless.

The following is an overview of the activities that are actually improved by the use of automatic storage systems:

- In automatic storage systems, stored goods are inventoried in real time. Thus, we can say that the goods placed in the machine are almost digitalized, since stock is recorded via software or interfaced with the management system and this undoubtedly translates into less waste.

- When the order is processed, the storage system automatically transfers the goods to an ergonomic workstation/area, where they are picked by the operator from compartmentalized trays. This increases productivity: the operator no longer has to move around the warehouse, saving time and energy.

- Operators receive the goods without being exposed to moving parts and do not need to handle heavy loads or operate machinery. The automatic storage system trays arrive at the workstation at an ergonomic height, suitable for picking.

2) Picking optimization

Ensuring high productivity levels in terms of picking is one of the objectives of anyone managing a warehouse. With Modula systems, products can even be taken from trays using bar codes: in this case, a Copilot console with a user-friendly interface assists the operator. This system ensures that the correct item is delivered to the operator for the fulfillment of the order: there is no need to move around the warehouse to find the required goods, to the full benefit of productivity and efficiency, which increase significantly while picking errors decrease.

Picking errors can be further reduced thanks to the use of simple visual aids. These tools, which include laser pointers, external picking monitors, put to light, and LED bars, are designed to help the operator to easily identify the items to be picked or those running out.

More efficient picking requires even more innovative solutions: to increase the performance of automatic storage systems, it is possible to combine multiple picking centers, for example using automatic horizontal carousels.

With Modula’s WMS software, users can prepare sets of orders to be fulfilled simultaneously, with some essential benefits:

- productivity increased up to 65%

- increased accuracy in order preparation

- reduction of picking times.

An interesting fact, related to the improvement of picking operations, makes the incredible advantages of automatic storage systems immediately clear: the shelves of a traditional racking system allow a picking operator to pick up to about 40 order lines per hour. With Modula automatic vertical and horizontal storage systems, the picking speed can reach an astonishing 150-250 lines per hour. This simple fact demonstrates how a single person can do the work previously done by 3 or 4 workers.

Pillar 3: Automatic vertical and horizontal storage systems: Their effect on the economic sustainability of warehousing activities

Economic sustainability, which concerns activities aimed at ensuring business success while taking care of the environment, is the last pillar that we will consider in our analysis. Modula’s automatic vertical and horizontal storage solutions offer immediate advantages such as those presented below.

1) Reduced storage and transportation costs

Costs due to off-site storage facilities or arising from freight transport operations between different locations are drastically reduced or eliminated. Less space is needed, in some cases even reaching a reduction of 90%.

2) Fewer returns

There are many advantages resulting from storage and order management solutions designed according to ergonomic principles. The achievement of better working conditions, one of the most immediate effects, leads to benefits such as the reduction of turnover and of sick days per individual employee. Picking operations also become more efficient and accurate, because they are supported by aids that:

- make picking more accurate;

- reduce errors in order preparation;

- reduce returns;

- lower the additional costs associated with packaging waste and shipments;

- improve the company’s brand image.

3) Improved security

The more careful management of storage prevents regrettable and unfortunate situations which even the most stringent safety procedures have not yet been able to eliminate, for example:

- goods (even highly valued) sent to the wrong destination;

- circulation of the wrong products;

- circulation of expired or obsolete products;

- circulation of products not yet released to the public.

The implementation of access tracking and access through user authentication by means of EKS, RFID and badge readers, make storage environments even more secure and protected; even individual products can be made accessible only to authorized personnel.

If we focus on the software developed for storage management, we can note that the WMS can keep track of the SKUs stored in the relevant storage units. Inbound and outbound goods are continuously tracked and the stock is always synchronized with the relevant databases as a result of continuous monitoring that also simplifies the inventory process, saving time and resources.

Conclusions

Sustainability is one of the main strategic objectives for many companies as part of the actions aimed at growth and global competitiveness. From the initial small group of “green” companies, the new sustainable approach has now expanded to companies from numerous industrial sectors.

Attention to technological evolution as well as economic and social factors is the foundation of modern automated storage solutions like those developed and manufactured by Modula.

Want to know more?