In the era of the digital economy, e-Commerce is experiencing a real explosion, with disruptive effects on the entire Supply Chain. Consumer expectations and the way they shop are changing. In this context, new models have been developed to manage logistics and sales to meet modern consumer needs.

E-commerce in figures

This is an unstoppable trend: in 2019 sales exceeded US$3.53 trillion, by 2021 they are expected to reach a value of $4.5 trillion and $6.54 trillion in 2022. In 2020, the number of digital buyers is expected to exceed 2.05 billion, up to 2.14 billion in 2021. (Source: Oberlo)

We are talking about a 276.9% increase in world e-commerce sales in the coming years (Shopify), and 95% of purchases are expected to be made online by 2040 (NASDAQ).

Customer Experience

The world of online retail is increasingly competitive and the quality of the service provided, that is, sales, logistics, and distribution, plays a fundamental role in online sales. These aspects are actually becoming the real added value both in the relationship with customers and in the business to business relationships along the supply chain. The degree of customer satisfaction will take on new meaning and will be of crucial importance in the world of retail. The purchasing process must be efficient, with engaging purchasing methods.

Purchasing models closer to customer needs: BOPIS and BOSS

An omnichannel approach, long adopted by some giants in the sector such as Walmart, Target and Amazon, represents a current trend that is growing rapidly on a global scale. This approach puts the customers at the center of the digital transformation strategy of retailers, involving them in all channels and in all phases of the purchase process and offering them all possible options in order to facilitate the purchase. Let’s examine some omnichannel trends, namely BOPIS (Buy Online, Pick Up In-Store) and BOSS (Buy Online, Ship-to-Store), both able to greatly improve the degree of customer satisfaction and to play a crucial role in lead conversion.

Let’s first try to understand what these purchase models are and why they work.

BOPIS – Buy Online, Pick Up In-Store – implies an online purchase and the collection of the items at the store.

BOSS – Buy Online, Ship to Store – is a process that comes into play when BOPIS orders are out of stock. When the ordered item is not available, the BOSS system recovers it in the nearest branch, minimizing the percentage of lost sales.

Why do these purchase models work?

- First of all, they are able to combine the ease of an online purchase with the immediacy and convenience of finding goods in a physical store, offering an integrated and dynamic shopping experience.

- Not only that, these strategies ensure great savings. Shipping to stores rather than to the end customer is much cheaper and undoubtedly leads to great savings in packing and labor costs in the preparation of orders.

- Further savings also result from the reduction in returns and the management of the so-called reverse logistics.

- The risk of stock outs for the most fast-moving products will be drastically reduced, as well as the inventory of slow-moving items, thereby translating into an optimization of inventory and space.

- The BOPIS strategy is also a way to attract customers to the store. More traffic and probably more sales, as a visit to a store increases the possibility of conversions.

Advantages for the seller but also for the customer, who sees his/her customer experience improve significantly thanks to greater flexibility, customization and a wider range of purchase options in different channels.

Why does customer experience improve with these strategies? Firstly, the customer can see the purchased item before taking it home, try it and decide whether to finalize the purchase or not, also avoiding annoying lines.

The customer no longer needs to worry about tracking the order, since it will arrive in the store. Last but not least, for the customer the purchase will be more economical, since there are no shipping costs (incidentally, shipping costs are still the main reason for abandoning the shopping cart in online purchases).

Micro-Fulfillment Center (MFC) for omnichannel retail

In a hyper competitive and increasingly demanding market such as the retail market, where the required lead time is increasingly tight (fast delivery time is one of the most common requests of online buyers), the implementation of Micro-Fulfillment Centers (MFC) is helping companies speed up deliveries and reduce the distance between fulfillment centers and their customers.

Micro-Fulfillment Centers are highly automated mini-distribution centers able to autonomously assemble online orders and reduce the “last mile” delivery costs.

Thanks to their “micro” dimension, these robotic systems can be located directly in large cities, behind one or more shops or in adjacent buildings, and represent a valid alternative to the traditional centralized distribution centers historically used for the supply of retail stores.

The micro-fulfillment model is certainly more suitable for omnichannel models such as BOPIS or BOSS.

Logistics: a fundamental driver for success in e-retail

Logistics and e-commerce are deeply connected, in fact logistics is often a critical success factor against which the retail giants measure themselves.

Companies that want to seize the online sales opportunity using certain purchasing models must be able to ensure speed, precision, and flexibility. Customers must be guaranteed what they want, how and when they want it.

To do this, every company involved in e-retail will have to invest in Lean logistics that includes automation, order management, inventory and stock management systems. An essential element for the functioning of purchasing models such as BOPIS or BOSS is, above all, precise inventory under real time control.

The first step towards adequate logistics ready to manage modern purchasing models could be the introduction of an automatic vertical storage system along the supply chain.

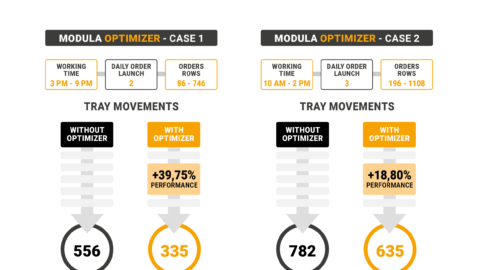

Automatic vertical storage systems are one of the possible technologies able to increase picking/hour performance, increase picking precision (and therefore decrease returns), and guarantee that inventory is continuously monitored and updated.

Being modular, an automatic vertical storage system can be adapted to any industrial environment, ensuring excellent footprint and volumetric performance.

Automation: the way forward to manage e-commerce logistics