Items in constant demand (also known as regular demand) are items that are not normally very difficult to manage.

These are actually products which are:

- Not subject to fashion trends and consumption is therefore similar from one year to the next.

- Not subject to seasonality – consumption is generally constant and there are no particular peaks or troughs at certain times of the year.

- They therefore have a reasonably predictablerate of consumption.

- These can be obtained or produced quicklyand easily in any quantity and at any time of the year.

These items are managed using periodic reordering throughout the year. If a certain quantity remains at the end of a period, these can be used to meet the needs of the next period.

In this situation, the problem of stock management consists largely of deciding what quantity to order and when to issue each individual order.

Such decisions are obviously based on assumptions made about current sales volumes and supply times.

Where do you store items in constant demand?

If we had to have a constant number of reorders of a particular product, it would be very useful to be able to store them in the same place, know immediately how many are in stock and have control over what condition they are in. In fact, if you are going to order large quantities of production materials in order to optimise costs and lower their purchase price, you will want to be sure you can store these materials where they will not deteriorate or be exposed to corrosive or damaging agents.

For this an automatic vertical warehouse would absolutely be the best solution to meet this purpose.

Your materials would be placed in a secure location, protected and kept away from dust, atmospheric effects, dirt and be completely under your control. Your materials and stock levels would be under permanent control, even months or years in advance.

Your materials will be perfectly preserved and stock levels under control.

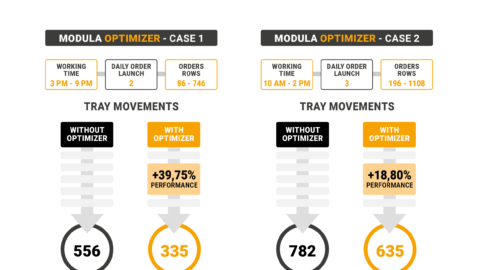

Products with the highest rotation located in the most frequently accessed trays would be automatically located close to the picking bay by the warehouse software so as to reduce waiting times and speed up picking.

Ideas for warehouse reorganization