The percentage of purchases made online has grown exponentially in the last few years: more than 320 million people in Europe made at least one purchase on an e-commerce site in the last year and almost 80% make at least one purchase a month.

This makes e-commerce a great opportunity for all businesses, enabling them to reduce the distance between their end customers and their products by enabling consumers to make a purchase from their own home, with a simple mouse click, using their computer or smartphone.

However, for businesses this poses a major question: how can they manage e-commerce logistics quickly and efficiently?

The first step is without a doubt to consider all the “routine” problems which might adversely affect the performance of an e-commerce operation, such as deliveries by suppliers or excessively bulky packaging. Then the entire issue of warehouse management has to be considered, if necessary with the help of experts in e-commerce and general logistics.

This article takes a closer look at various factors involved in preventing errors and improving the performances of an e-commerce warehouse, especially:

1. E-commerce: a new approach to logistics

From storage to freight to reverse logistics and returns management, from packaging to delivery: logistics as we have always known it has to evolve into e-commerce logistics.

The main aim is customer satisfaction, considering that customers expect to receive goods on time, intact and, above all, with no additional costs. To do all this it is essential to apply clearly defined strategies and review the warehouse’s whole logistics management model.

2. Speeding up e-commerce picking operations: it’s much easier with automatic warehouses

One initial step in speeding up picking operations might be to consider a new solution as a replacement for shelving warehouses: one of the best options is definitely the automatic vertical warehouse.

In contrast with the traditional concept, in which the operator moves around inside the warehouse looking for the articles he needs, with the technology of an automatic vertical warehouse the goods are brought to the operator, who does not move from his workstation. All this allows tidy, safe organisation of goods, but above all allows faster picking operations, for e-commerce and in warehouses in general.

3. E-commerce logistics: warehouse management for faster reverse logistics

The introduction of e-commerce into businesses is a gradual process, which may take place in different ways depending on the organisation’s size. However, one factor must be considered even before the portal is opened: how can reverse logistics, meaning simply returns, be accelerated within the warehouse?

Reverse logistics is a major weapon in the battle for market shares: in fact, over a two-year period consumers tend to reduce their purchases by 100% on sites with a charge for returning goods, but to increase them by up to 457% on sites with free returns.

So efficient management of the return of products is essential to ensure complete customer satisfaction. It is estimated that about 10% of online purchases are returned to the seller, although in sectors such as fashion the percentages can be as high as over than 20%.

This implies the need to reorganise the whole logistics operation, with the aim of speeding up reverse logistics as much as possible, in order to minimise the associated costs.

4. Modula automatic warehouses: the integrated solution for e-commerce logistics

Modula automatic vertical warehouses are the appropriate solution for all the logistics problems of an e-commerce business: created to make full use of all the height available, saving floor space, vertical technologies are suitable for any type of product, in any industry or sector, since they can be customised with different payloads, heights, sizes and accessories.

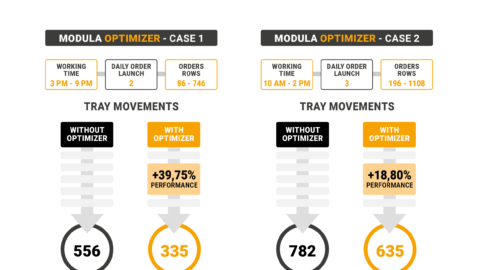

Modula allows you to store goods in an organised, clean, secure and fast system, reducing the number of movements operators have to make and avoiding damage to your goods. Packaging, cardboard boxes and returned goods can be stored in a single warehouse, regardless of size and weight. A single storage tray has a payload of 990 kg and remains balanced even if the load it contains is off balance. What’s more, Modula can calculate how the storage trays should be placed to optimise the gaps between them.

Automation: the way forward to manage e-commerce logistics