How difficult is it to manage an automotive warehouse with old traditional shelving?

How to organise the warehouse is a puzzle for lots of companies operating in the Automotive sector. With all the accessories, spare parts and mechanical components you need, filling up one, two or three buildings was just too easy. Rent, upkeep and maintenance of these spaces represents a huge expense for a company’s coffers. As a consequence of a company’s core business, a whole series of activities have to be carried out on a routine basis. These are maintenance, repair, refilling of consumables and cleaning of machinery used in production. Each operation of this type requires materials, tools and products which need to be physically located somewhere, easy to access and under constant control to avoid delays or stoppages.

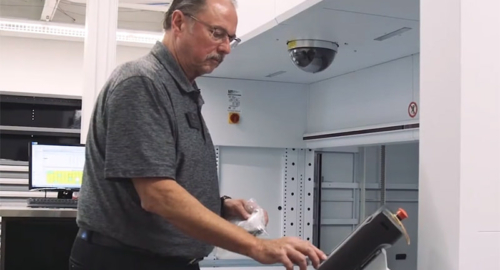

Modula, the automated vertical warehouse that transforms your production flow

Being accurate and having to prepare a large number of orders per hour are determining factors which require a new approach to logistics and warehouse management. More orders and more shipments with zero mistakes but with better working conditions for operators who no longer have to walk 70% of the time looking for items while shipping a much higher number of orders, because everything is concentrated in one place. All this thanks to the visual aids supplied with a vertical warehouse which help operators during picking and refilling. No more mistakes, no more late orders, more efficiency and more satisfied customers. Which departments should Modula be located in? In some automotive industry firms, the automated vertical warehouse acts as a storage buffer for parts or components which need to be stored for a certain period before being forwarded on to the next production phase (e.g. as part of a drying or curing process). Once stored, the items are then retrieved by operators or articulated robots which return them to the production line. In other cases, the Modula vertical warehouse is placed in an intermediate stage of the production process and used as an emergency buffer. Should a production phase upstream of the Modula become blocked, materials are then pulled directly from the Modula to keep the production process flowing. If the problem is downstream, what has been produced so far can be stored and so the Modula gets filled with semi-finished products.

Modula can be constructed with opposed bays (front & back) so that operators can load ready materials into one side of the warehouse, and assembly or production operators can pick them from the bay on the other side. When supplying production lines, reliability, speed and the wide range of automatic internal and external bays offered by a Modula system have turned out to be an essential lever for improving production performance. For dealerships and spare parts suppliers providing on-site service, the major advantage is having constant control over inventory. This means a significant reduction in resupply times for spare parts and in turn helps maintenance providers in their day-to-day work. Modula’s high storage density allows workshops to make the most of their available space, saving up to 85% of floor space compared to traditional warehouses.