Modula can be integrated with a variety of solutions and partners for robotic automation.

Let’s take a look at some of them in detail.

Robotic integrations with Modula

Efficient storage and handling of materials, picking and depositing operations, all managed by a simple and intuitive warehouse management software are some of the objectives of modern intralogistics management.

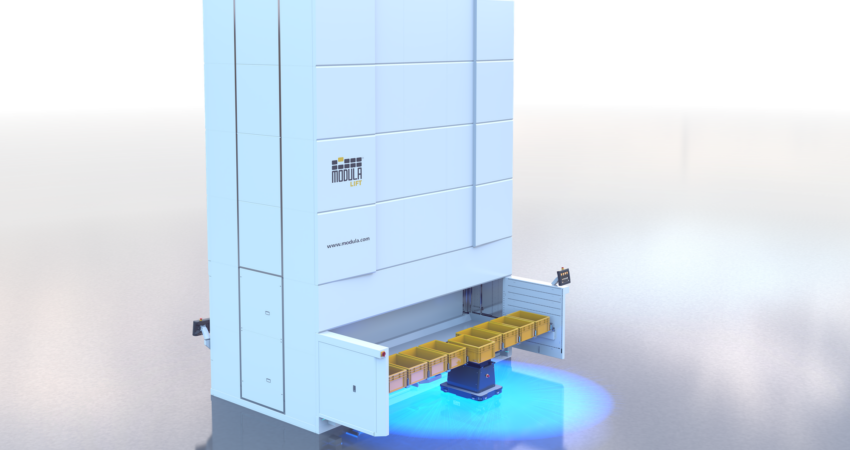

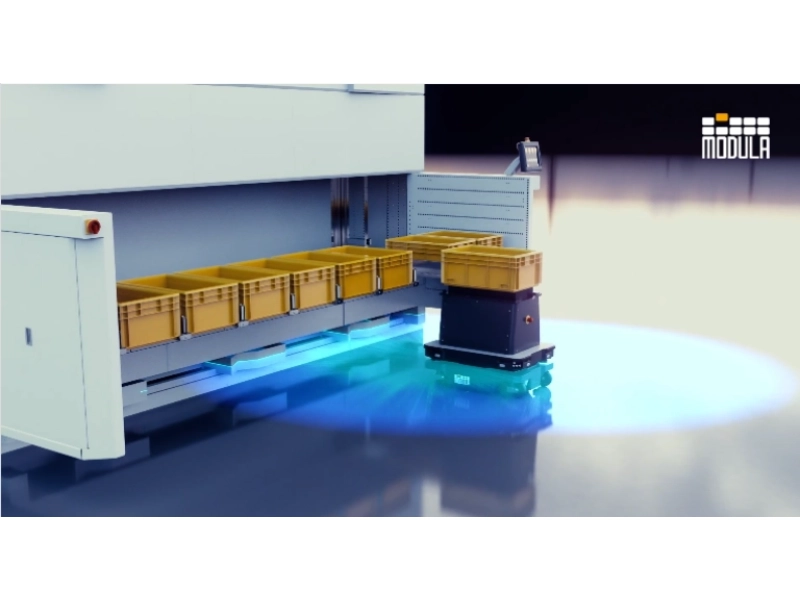

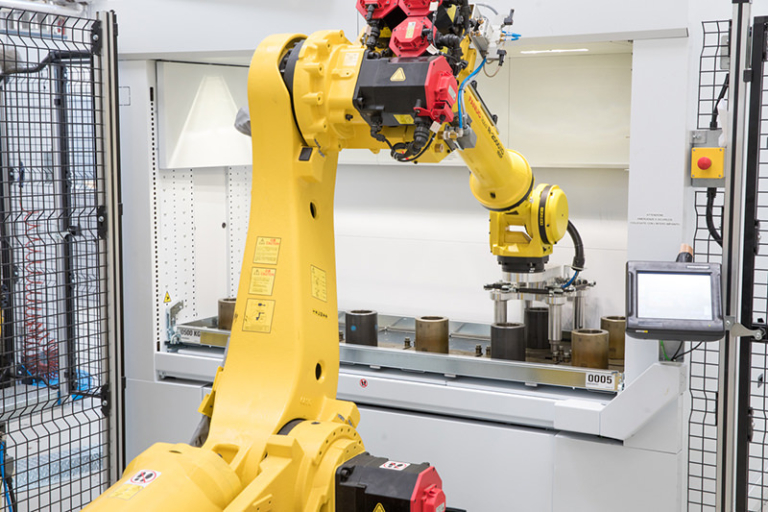

Leveraging industrial robotization and automation for logistics, a vertical storage solution integrates seamlessly with advanced robotic solutions. Smart automation technology enables fluid interaction between industrial automations and robotics components. The result? A highly efficient robotic warehouse, with improved operational efficiency and optimal use of space.

Automation with robots, including warehouse robots and robotic cabinets, is the future of logistics, guaranteeing unprecedented precision and throughput. Modula automatic solutions and Modula automation integrations have a remarkable capacity to coordinate complex systems, for optimal warehouse operations management.

By integrating robotic systems and robotic solutions for warehouses, you can significantly improve robotic efficiency, slashing downtime and boosting productivity. With Modula system integrations and smart automation technology, robotics is revolutionising industrial processes: warehouse automation is now an achievable reality that can truly benefit modern businesses.

Different automation solutions can be made to work together, to optimise production flow and supply chain management in complex systems or for specific purposes. This is a particularly effective strategy for streamlining the management of production and supply chain processes.

Robotic technology is an amazing resource for any business that needs to manage picking, replenishing, refilling or automated movement operations. That’s why robots are gaining in popularity across all industries, and industrial robotics is seeing rapid growth across a vast number of applications. Robotic solutions are also becoming increasingly affordable, as well as useful, for businesses in every sector.

Many of these operations can now be automated by integrating Modula’s automated robotic solutions with autonomous mobile robots (AMR), anthropomorphic robots, or autonomous mobile robots like MIR (Mobile industrial robots).

Due to advances in technology, these machines are fast becoming an essential element of warehouse logistics and automated picking operations.