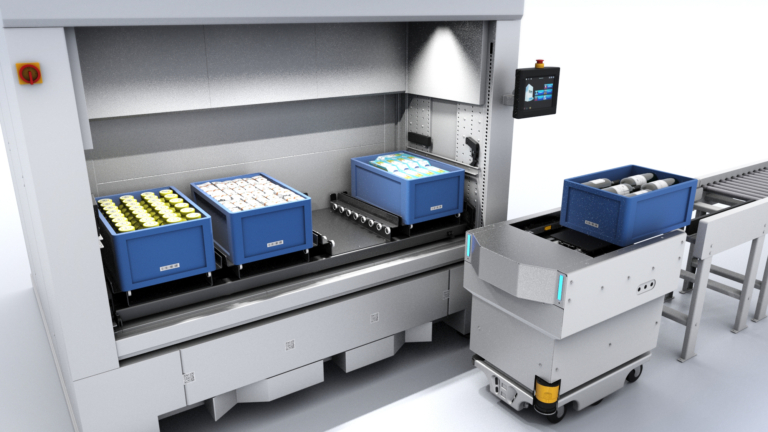

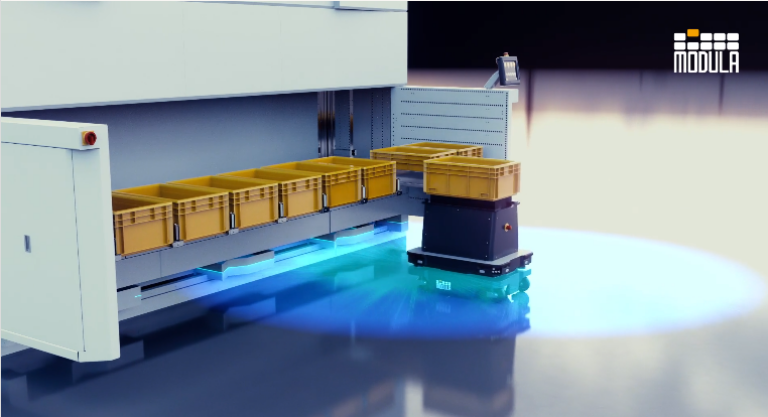

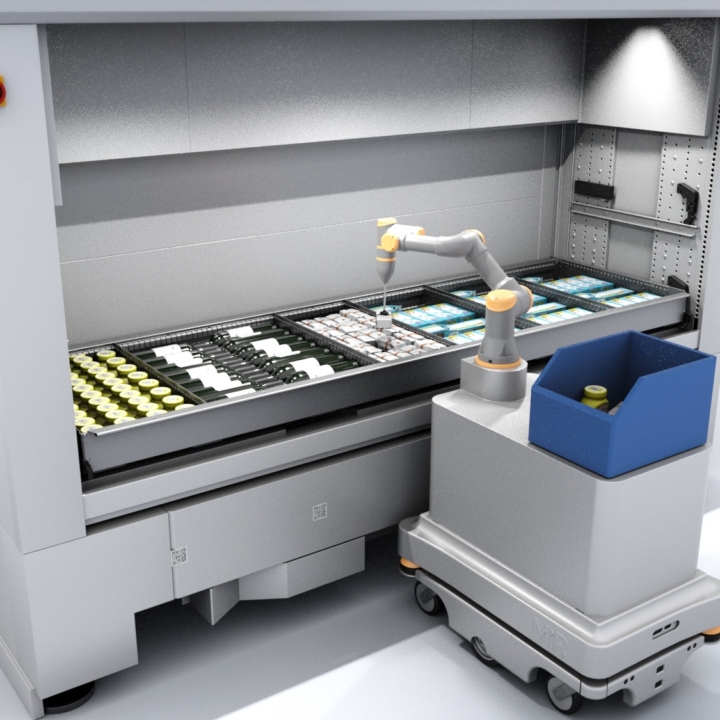

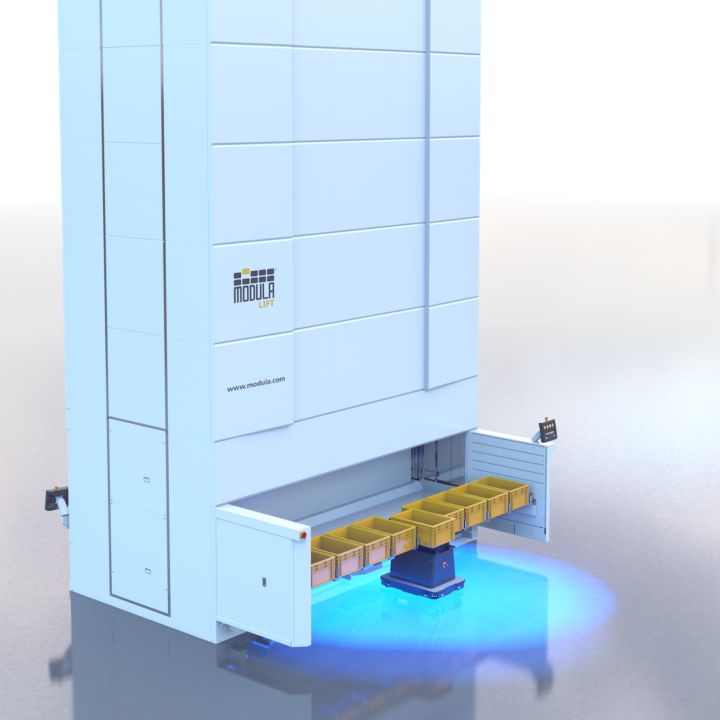

AMRs are 100% mobile and autonomous systems that represent an alternative to conveyors when it comes to optimising warehouse processes

To make the operator’s job easier, AMRs can be used directly in the bay. In this case, the AMR robot collects the material the operator has picked from the Modula.

Following the instructions given by the Copilot system, which indicates the storage location, the quantities and the operations to be carried out, the operator picks the required products from the tray and places them on the AMR. The robot follows the operator throughout the process, streamlining the workflow by moving autonomously to also serve other departments with no need for human intervention.